Are you getting ready to get your business into the storage business? Are you considering what is storage capacity planning spreadsheet to do? Well, let me let you in on a little secret. It is only about a 1% of the storage industry that actually takes the proper inventory planning seriously.

Storage utilization is a vital part of your system that should be a top priority. But, not many companies are using this strategy to improve their operations, as they either consider it too much of a “cumbersome” process or think that it is too difficult to implement.

The real answer is that with the proper storage utilization and inventory, the actual size of your storage budget can actually be kept to a minimum, which in turn can cut your operations costs dramatically. The stored space is more valuable than its cost value and can be divided into multiple units. This way, it allows you to trade it at the price you pay for storage in other areas such as items in storage and even goods which have been delivered to you, so you could make an allowance for future returns.

Storage Capacity Planning Spreadsheet – A Great Way to Improve Your Inventory

Storing those units over time will allow you to make an accurate comparison with the true value of the items in storage. And, by not filling up all your storage spaces, it also gives you more room for future growth. This will allow you to purchase more storage spaces at lower prices, making your new inventory much more valuable.

If you have too few units, you will end up wasting a lot of money in unnecessary costs. In this case, you would end up being under-spending and seeing less returns than what you had expected, which means higher maintenance costs, which would make your business a burden to your customers.

Storage utilization makes the right amount of units available to meet your demand at any given time. It will keep you from having to use the floor space, while still making the space for future growth in storage space.

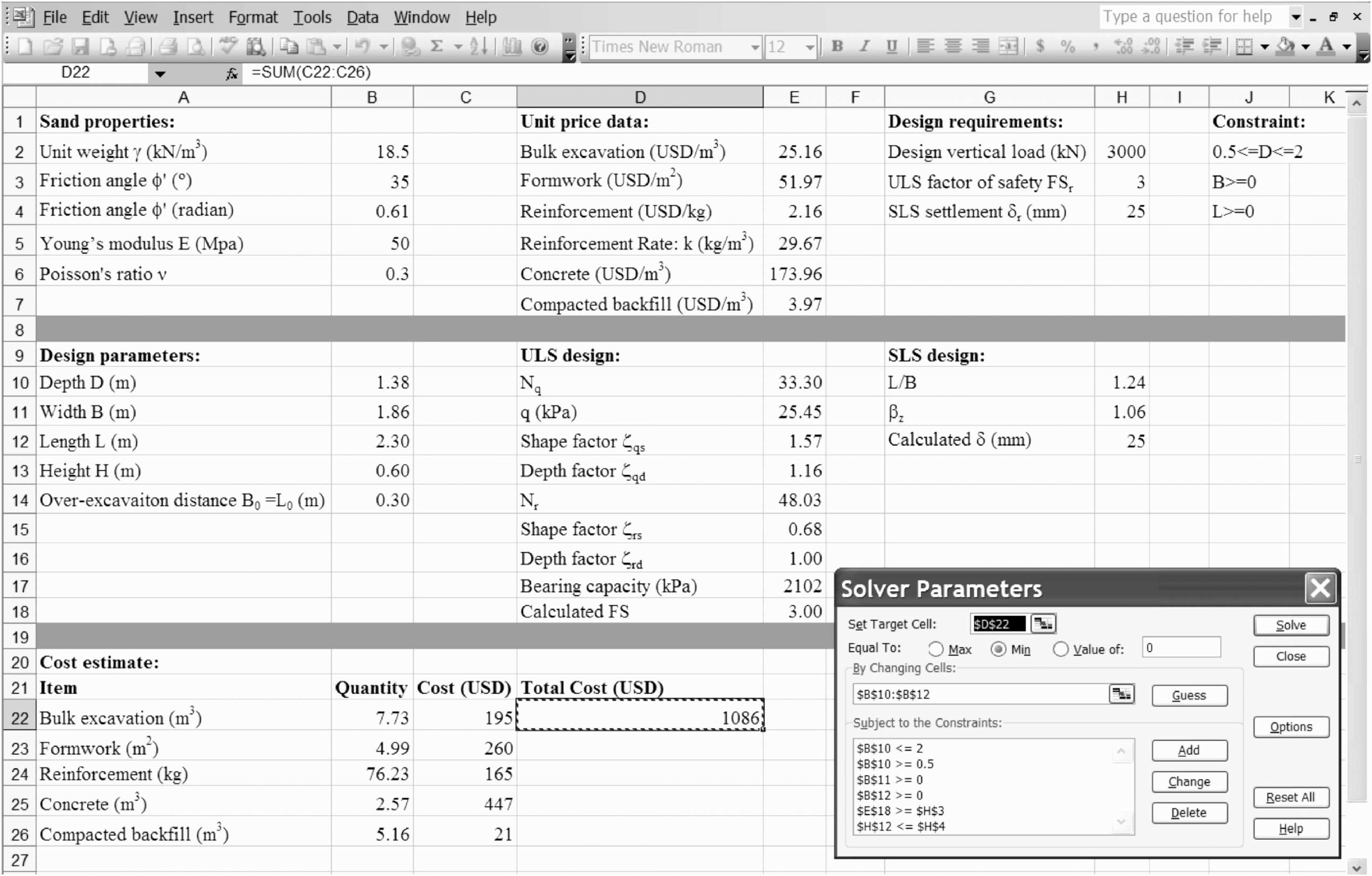

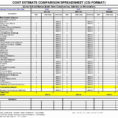

To know how much storage utilization to allocate to each category of product, you can look at the prices of the items in your storage costs. With this information, you can determine how much space you will need to store what amount of inventory and at what price.

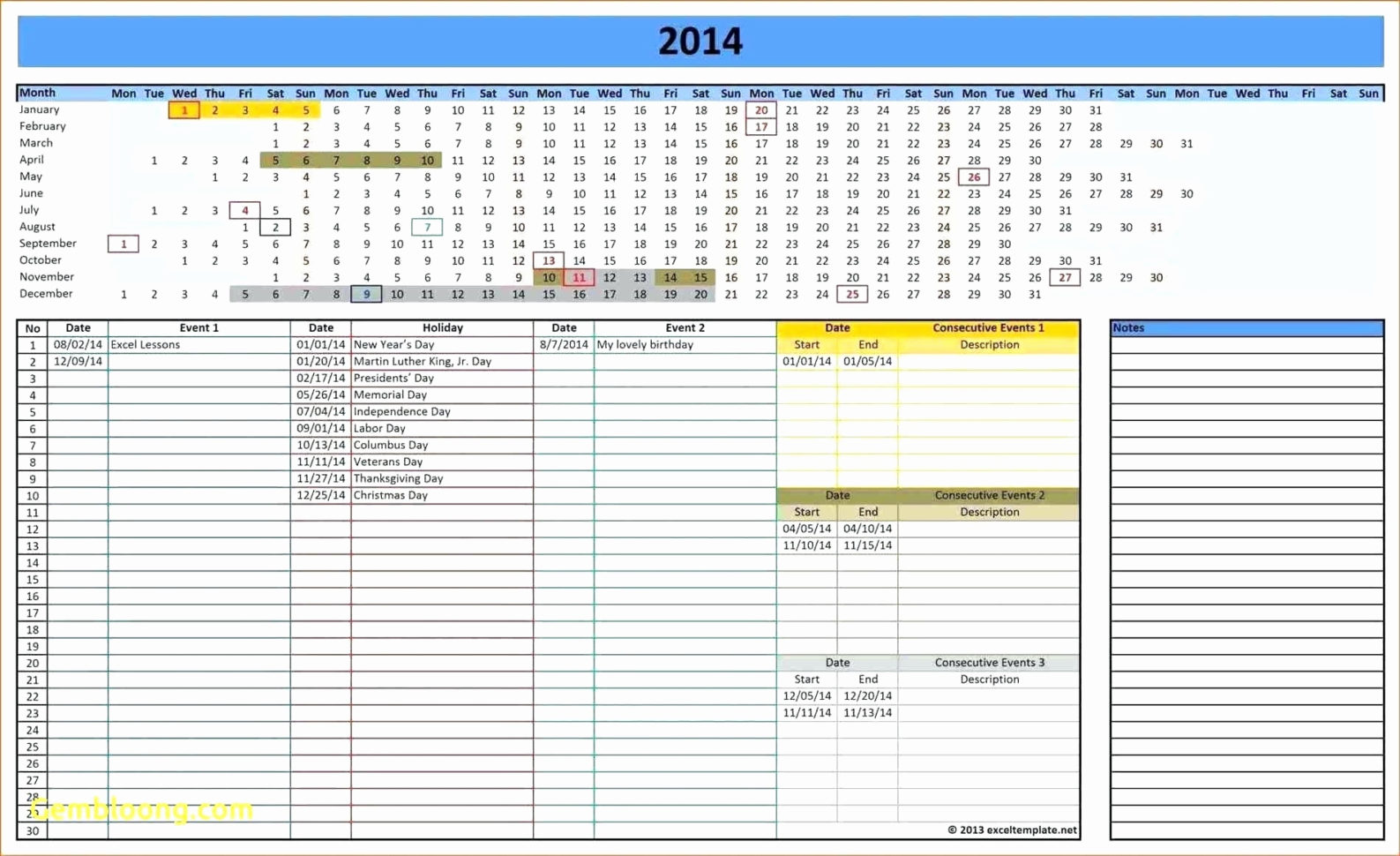

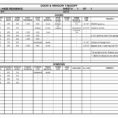

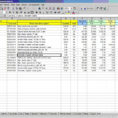

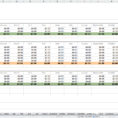

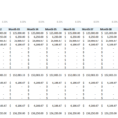

It will be very helpful if you are using a spreadsheet that can give you the overall inventory cost per unit at any given time. This will allow you to simply divide the total cost of all units by the total number of products in your inventory.

Keep in mind that not all storage capabilities are created equal. Some facilities can hold more items than others, and some can only handle larger containers. This is a matter of concern for every owner, so you need to make sure you get the right kind of facility that suits your needs.

When you buy this storage capacity planning, make sure you go over the rules of the facility, what kind of inventory to store, what is allowed in storage and how to make all the adjustments you need to make to account for those and many other factors. This is a guide you can refer to when purchasing a facility to house your inventory.

There are a lot of storage capacity planning software programs available online, so you don’t have to spend a fortune to get the right solution. If you don’t like the software, you can find your own storage software solution by contacting a storage planning consultant. PLEASE LOOK : stamp inventory spreadsheet

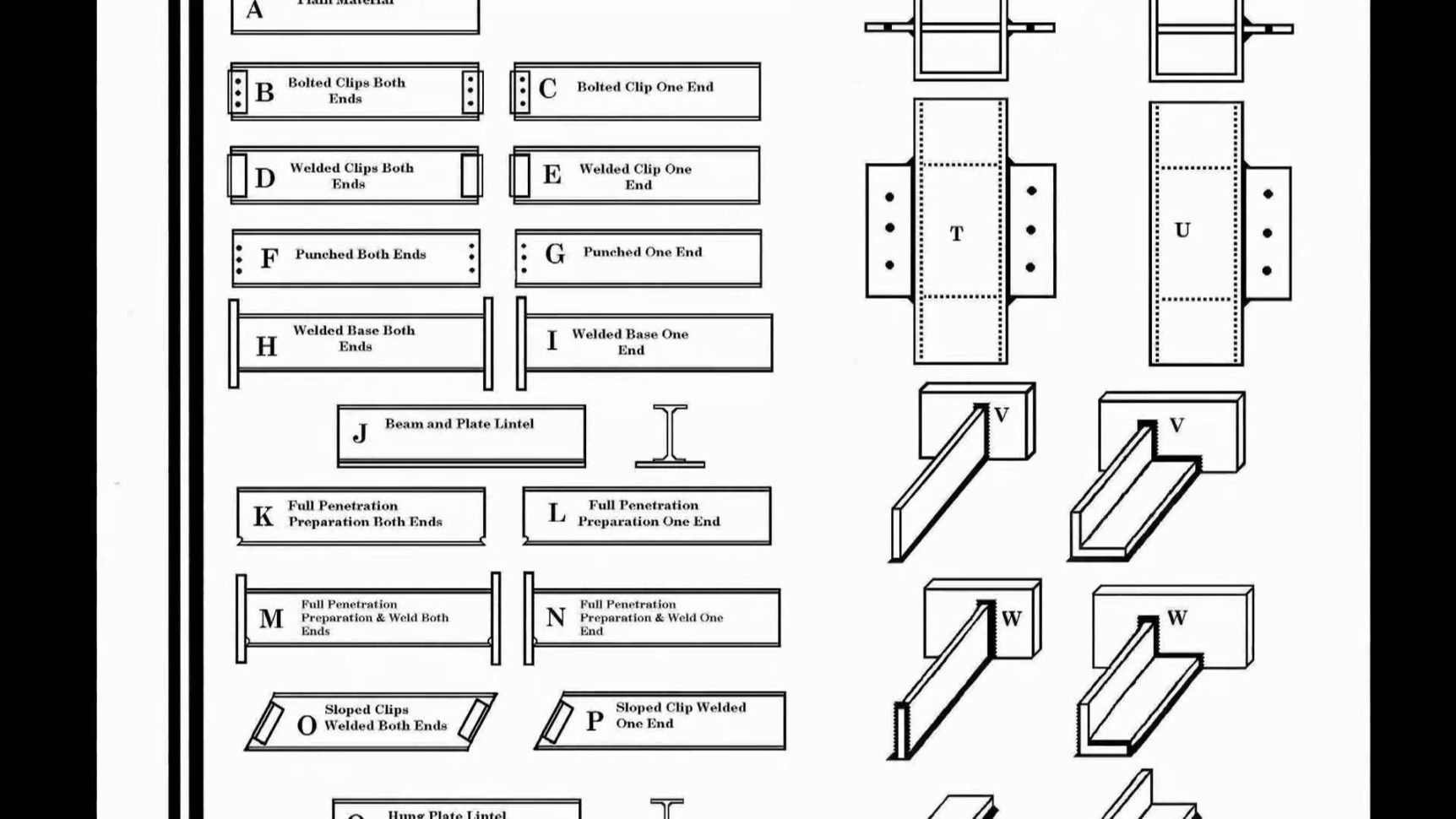

Sample for Steel Takeoff Spreadsheet